Custom Hardware & Firmware Development for AI and Embedded Systems

Design custom electronic devices — from idea to mass production.

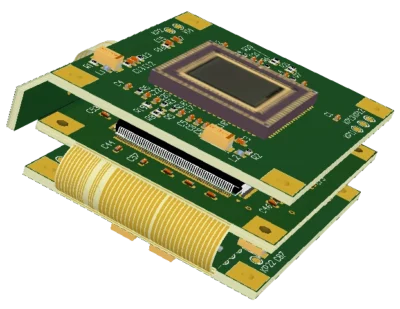

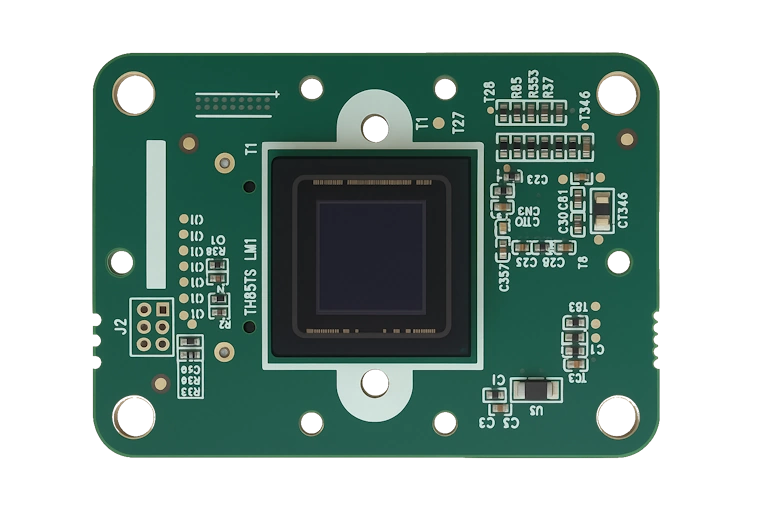

Expertise in AI Vision and Embedded Systems Engineering.

Expertise in AI Vision and Embedded Systems Engineering.

Full-cycle development of custom electronics — hardware, firmware, and embedded software.

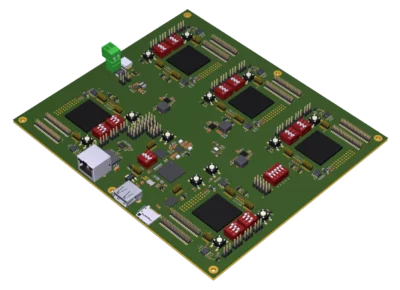

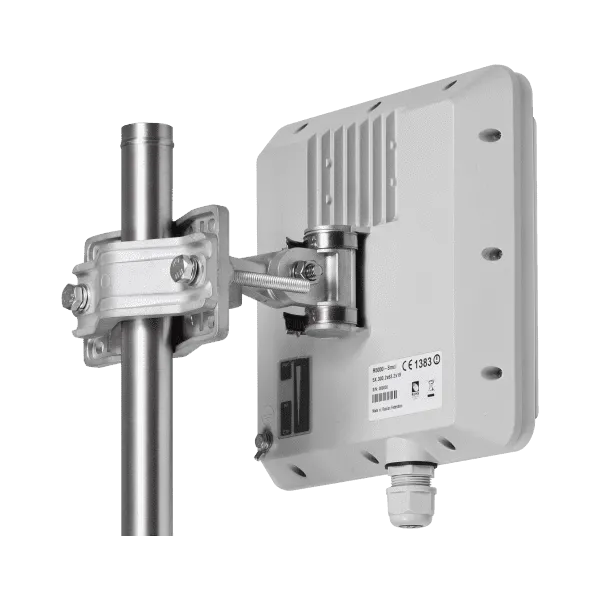

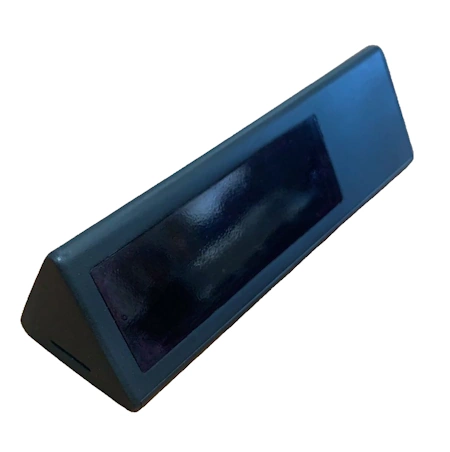

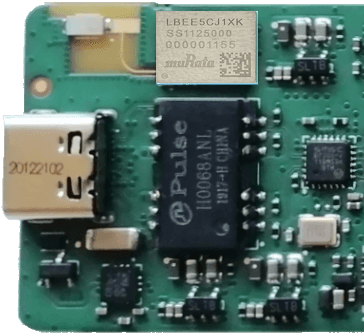

Specializing in AI camera systems and edge computing solutions.

From prototype to production — deliver reliability, scalability, and performance.

Specializing in AI camera systems and edge computing solutions.

From prototype to production — deliver reliability, scalability, and performance.

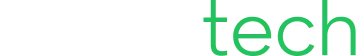

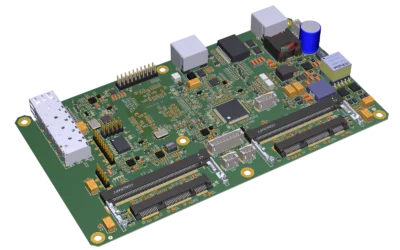

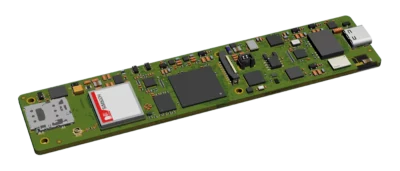

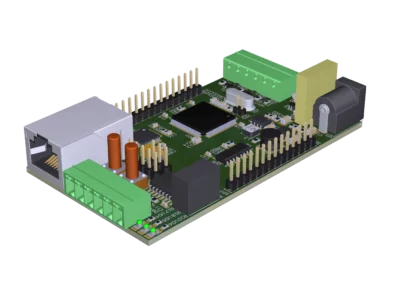

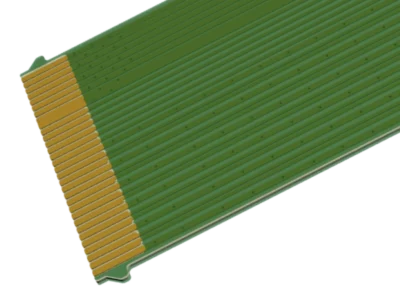

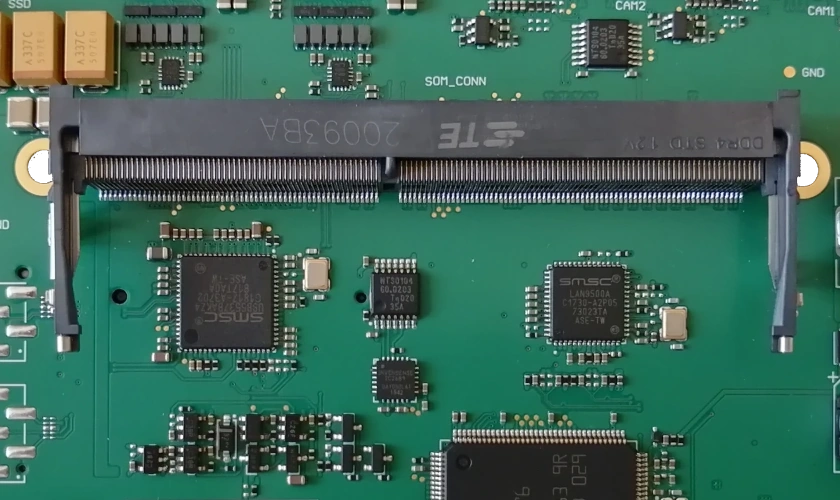

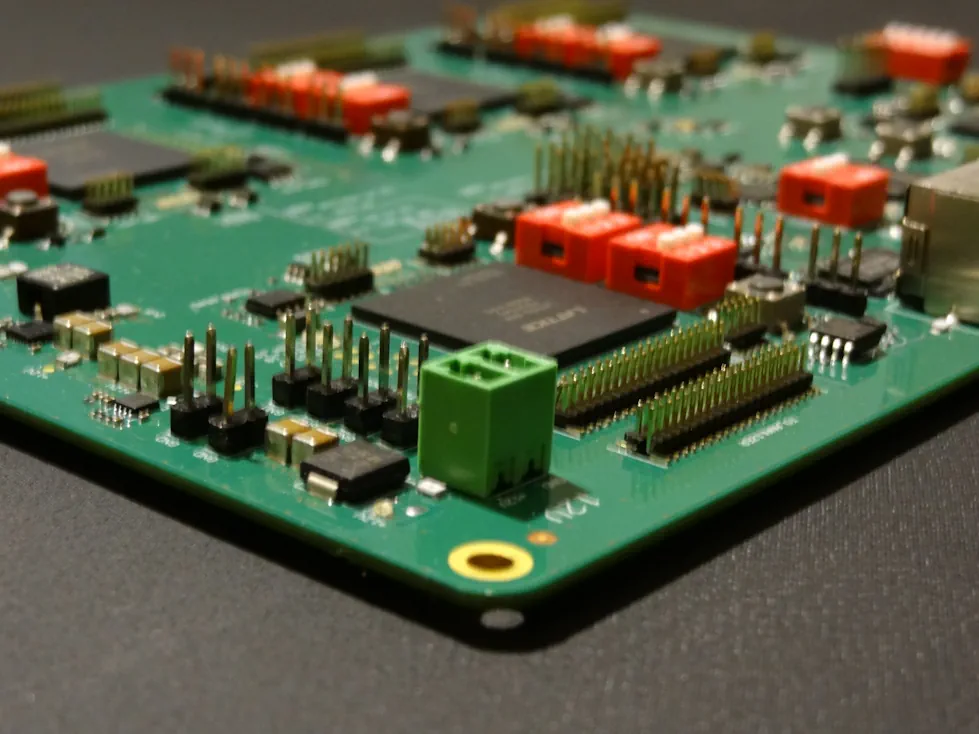

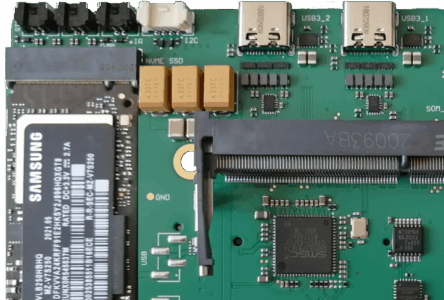

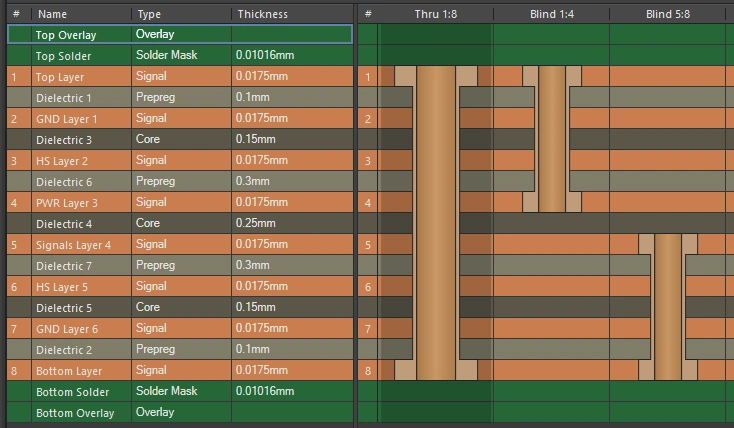

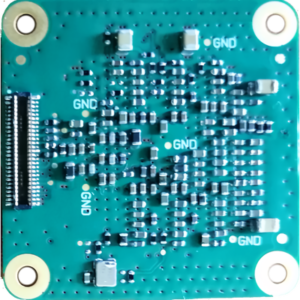

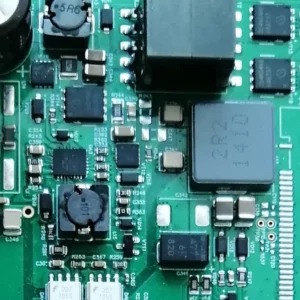

Custom circuit and board design

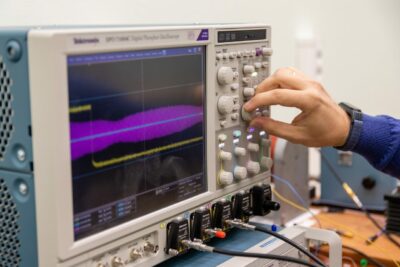

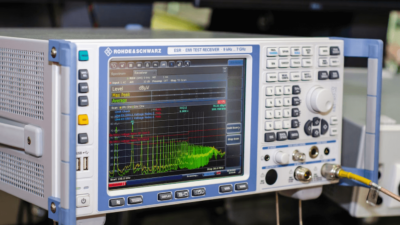

Rapid prototyping and validation in in-house lab

Full hardware & firmware integration

Production-ready documentation and support

Full-cycle R&D

In-house laboratory

4.9/5 Ratings